Why Mass Containers Are Important for Sustainable and Cost-efficient Transportation

Mass containers play a crucial role in modern-day logistics. They promote the efficient motion of huge quantities of items, therefore maximizing transportation processes. This approach not only lowers costs yet also minimizes environmental effect via lower exhausts and waste generation. As sectors seek more lasting techniques, the adoption of mass containers is coming to be progressively significant. What effects does this change hold for future logistics and supply chain management?

The Advantages of Making Use Of Mass Containers in Logistics

Mass containers transform logistics by improving performance and sustainability. These containers permit the transport of huge amounts of products in a single journey, significantly minimizing the number of journeys required. This not just improves operations yet additionally reduces labor expenses connected with handling, packing, and dumping. Furthermore, mass containers are created to maximize room usage within transport cars, making sure that even more items can be shipped simultaneously.

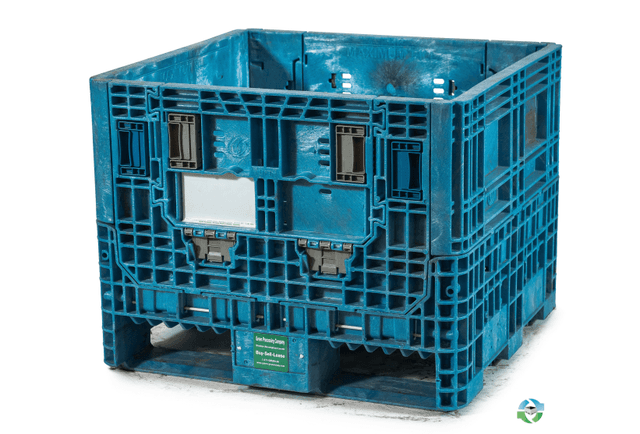

The standardization of mass containers also simplifies the logistics procedure. With consistent measurements, they can be conveniently stacked and stored, resulting in boosted warehouse monitoring. Mass containers usually feature resilient materials that secure materials from damage throughout transportation, thereby decreasing product loss and increasing total dependability. Therefore, businesses can experience enhanced supply chain performance, inevitably bring about increased productivity and customer satisfaction. This mix of factors makes mass containers a critical asset in contemporary logistics.

Ecological Influence: Lowering Waste and Carbon Footprint

As markets progressively prioritize sustainability, the adoption of mass containers has actually arised as an essential approach for decreasing waste and decreasing carbon impacts. These containers lessen using product packaging materials, such as boxes and plastic, consequently significantly lowering total waste generation. By settling shipments, mass containers improve transportation performance, enabling more products to be transported per trip. This reduction in journeys directly associates with lower greenhouse gas exhausts, adding to a smaller sized carbon impact.

Mass containers can frequently be reused or reused, additionally mitigating ecological impact. The sturdiness of these containers guarantees they can withstand several transportation cycles, lowering the demand for single-use choices. used bulk containers. By improving logistics and advertising efficient resource use, bulk containers not just support sustainable practices yet also urge industries to straighten with global ecological objectives. Eventually, their application shows a dedication to ecological stewardship and responsible resource management

Expense Savings: Just How Bulk Containers Lower Transport Costs

While many business look for ways to improve their profits, making use of mass containers presents a substantial possibility for decreasing transportation expenses. Mass containers make the most of the quantity of products moved, enabling services to deliver bigger quantities at as soon as. This efficiency lowers the number of journeys needed, straight decreasing fuel prices and minimizing labor expenses linked with loading and unloading.

In addition, mass containers typically include streamlined styles that optimize space utilization within transport automobiles. This implies fewer voids, bring about much more effective use offered capacity. In addition, the toughness of bulk containers can reduce the risk of product damages during transit, minimizing losses and making sure that more goods show up undamaged.

Enhancing Supply Chain Performance With Bulk Storage Space Solutions

Bulk storage options play a vital function in boosting supply chain efficiency by maximizing stock monitoring. By combining products right into fewer, larger containers, services can greatly minimize managing prices connected with frequent transfers and handling. This streamlined technique enables better monitoring and management of stock, inevitably causing boosted operational performance.

Structured Stock Management

Reliable stock monitoring is essential for maximizing supply chain operations, particularly when organizations take on bulk storage options. These options enable businesses to maintain higher supply levels while lessening the frequency of replenishment. By combining products right into bulk containers, business can enhance their stock procedures, reducing the intricacy connected with tracking numerous smaller packages. This technique helps with accurate supply matters and enhances forecasting precision, allowing for more enlightened decision-making. In addition, bulk storage remedies streamline warehouse company, making it much easier to find and accessibility products when needed. As a result, companies can achieve an extra reliable stock turn over rate, inevitably refurbished bulk containers enhancing general supply chain performance and reducing the likelihood of stockouts or overstock situations.

Reduced Handling Prices

The implementation of mass storage space options not just streamlines stock monitoring but likewise substantially decreases taking care of prices across the supply chain. By combining materials into bulk containers, companies lessen the requirement for constant handling and transfer in between various storage and transportation systems. This approach cuts down on labor prices connected with loading, discharging, and relocating smaller packages. Furthermore, mass storage space lowers the frequency of deliveries, bring about reduced transport costs and reduced gas consumption. Because of this, companies can optimize their logistics procedures, permitting an extra reliable allocation of resources. Eventually, minimized managing prices contribute to enhanced total supply chain efficiency, fostering an atmosphere that supports both sustainability and financial stability.

Convenience of Bulk Containers Throughout Various Industries

Although numerous markets have distinct demands for transport and storage space, bulk containers have become a flexible remedy that meets a variety of requirements. These containers, ranging from huge containers to specialized storage tanks, can accommodate diverse products, including liquids, powders, and granules. In the agricultural industry, mass containers help with the transportation of plant foods and grains, while the food and drink industry utilizes them for ingredients and completed products. The chemical industry depends on bulk containers for safely transferring hazardous materials, guaranteeing compliance with security regulations. In addition, building companies take advantage of bulk containers for carrying accumulations and other materials. Their adaptability expands to various settings of transportation, consisting of vehicles, trains, and ships, enhancing logistical performance. This convenience not only streamlines procedures throughout various sectors however additionally promotes sustainability by decreasing product packaging waste and enhancing room in transit. Bulk containers play a crucial duty in modern supply chain monitoring.

Future Trends wholesale Container Usage and Sustainability

The future of mass container usage is progressively shaped by ingenious materials advancement that improves sustainability. Additionally, automation in logistics guarantees to simplify operations, decreasing waste and enhancing effectiveness. Embracing round economic situation practices will additionally change exactly how bulk containers are created, made use of, and reused, fostering a more lasting transport landscape.

Cutting-edge Products Development

As markets significantly prioritize sustainability, innovative materials development wholesale containers becomes a considerable consider improving environment-friendly transport solutions. Producers and scientists are checking out biodegradable plastics, recycled compounds, and lightweight metals to decrease environmental effect. These products not just lessen waste yet also improve fuel efficiency by reducing the total weight of containers. Furthermore, innovations in clever products, which can adjust to varying conditions, enhance the toughness and functionality of mass containers. The integration of these ingenious materials straightens with circular economic climate concepts, promoting reuse and recycling. As the demand for lasting methods grows, the growth of such products will certainly play a crucial function fit the future of bulk container use in logistics and transportation.

Automation in Logistics

Substantial innovations in automation are positioned to transform logistics and the usage of mass containers, boosting sustainability in transportation. Automated systems, consisting of drones and self-governing vehicles, are improving the activity of bulk containers, minimizing the reliance on standard fuel-powered transport. These innovations enhance transmitting and filling processes, decreasing vacant miles and enhancing fuel effectiveness. Furthermore, automated stock monitoring systems improve monitoring and surveillance of mass containers, ensuring far better resource appropriation and minimized waste. The integration of the Net of Things (IoT) allows real-time data analysis, allowing proactive decision-making that lines up with sustainability objectives. As automation remains to progress, it is expected to drive even more technologies in mass container use, inevitably supporting more sustainable logistics methods and lowering the environmental effect of transportation.

Round Economic Climate Practices

Advancements in automation are setting the stage for a more incorporated technique to circular economic situation techniques in the domain name of bulk container use. As sectors progressively embrace sustainability, bulk containers are being designed for longevity and reusability. This shift not just minimizes waste yet additionally improves resource efficiency. Business are embracing techniques such as closed-loop systems, where made use of containers are gathered, reconditioned, and reintroduced right into the supply chain. Additionally, clever modern technologies track container life process, facilitating better monitoring and lowering ecological effect. The partnership between suppliers, logistics carriers, and end-users is vital in developing standards for sustainable container usage. used collapsible bulk containers. Future fads show an expanding emphasis on materials that are eco-friendly and recyclable, additional enhancing the round economy's principles wholesale transport

Frequently Asked Inquiries

What Materials Are Bulk Containers Commonly Made From?

Bulk containers are typically constructed from durable products such as high-density polyethylene, cardboard, steel, and aluminum. These products give toughness, security, and flexibility, making them appropriate for moving different products in various markets successfully.

Exactly how Do I Pick the Right Dimension Bulk Container?

Choosing the ideal size bulk container entails reviewing the volume of materials to be carried, considering managing devices compatibility, and appraising storage area demands. Proper size warranties effectiveness in transport and minimizes waste during delivery.

Are Mass Containers Reusable or Recyclable?

Bulk containers are commonly recyclable, made for multiple trips, boosting sustainability. Several can also be recycled, depending upon the products made use of. Choosing recyclable choices better supports ecological goals and decreases waste in transportation techniques.

What Safety Regulations Relate To Mass Container Transport?

Safety regulations for mass container transport include conformity with the Department of Transport standards, proper labeling of dangerous materials, architectural honesty analyses, and adherence to weight restrictions to assure safe handling and protect against accidents during transit.

Just How Can Companies Transition to Making Use Of Mass Containers Effectively?

Services can change to bulk containers by evaluating current logistics, training personnel on handling, spending in suitable equipment, optimizing stock monitoring, and working together with suppliers to ensure compatibility and effectiveness throughout the supply chain.

As sectors increasingly prioritize sustainability, the adoption of mass containers has actually emerged as a vital strategy for minimizing waste and reducing carbon footprints. By settling materials right into bulk containers, firms can improve their inventory procedures, reducing the complexity linked with tracking numerous smaller sized packages. As industries increasingly focus on sustainability, innovative materials development in mass containers emerges as a significant element in improving green transport services. Automated systems, including drones and independent lorries, are streamlining the motion of mass containers, lowering the reliance on standard fuel-powered transport. In addition, automated inventory administration systems boost tracking and tracking of mass containers, ensuring far better source allocation and lowered waste.